在弯曲木发展的过程中,艾克西德WMP如同一枚重磅炸弹,在行业内引发了广泛的关注。艾克西德 WMP横空出世,颠覆之前对弯曲木备料方式、弯曲维度以及加工工艺的所有认知!艾克西德依靠对于弯曲木加工的先进技术,在方方面面占有了很大的优势:

在弯曲木发展的过程中,艾克西德WMP如同一枚重磅炸弹,在行业内引发了广泛的关注。艾克西德 WMP横空出世,颠覆之前对弯曲木备料方式、弯曲维度以及加工工艺的所有认知!艾克西德依靠对于弯曲木加工的先进技术,在方方面面占有了很大的优势:

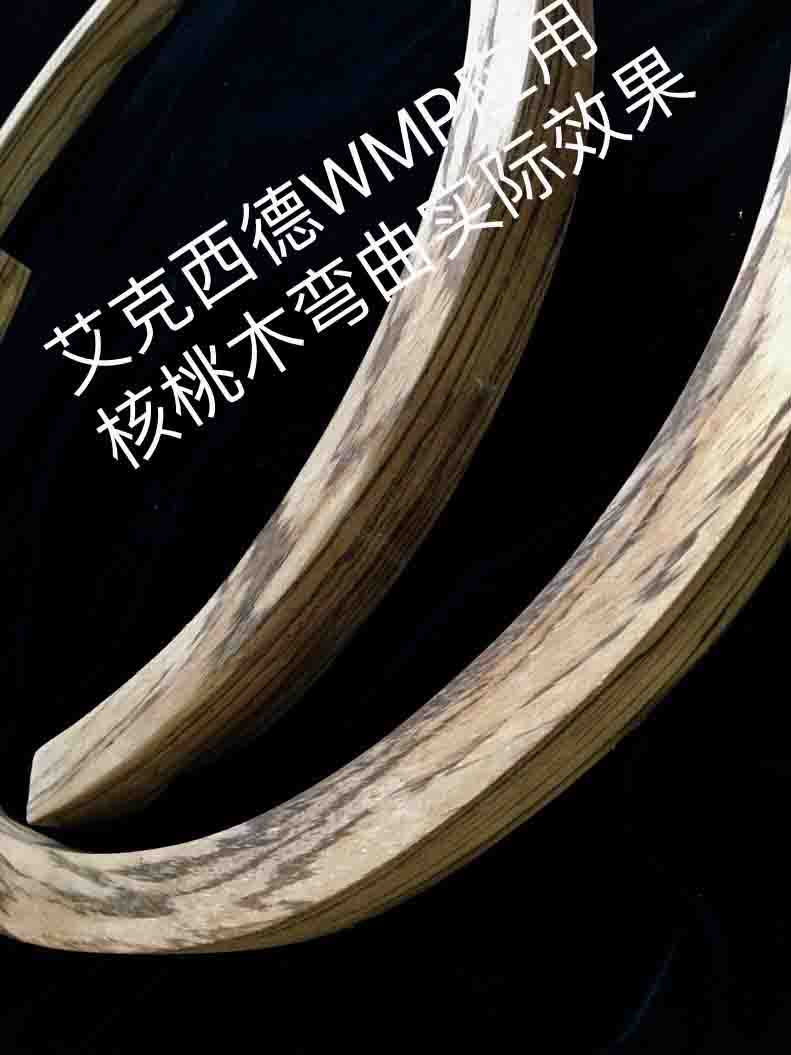

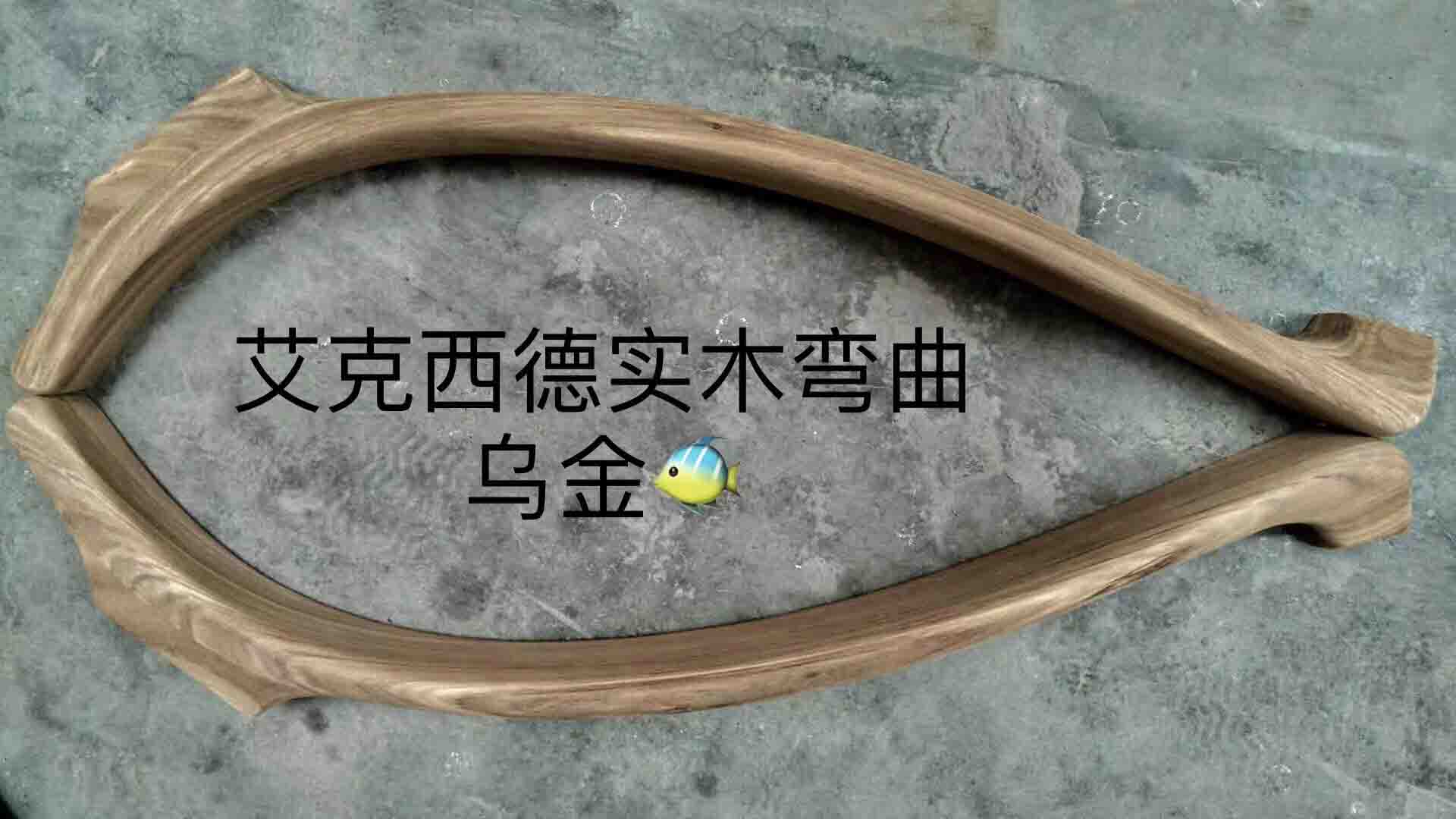

1.艾克西德的产品可以大大降低成本:WMP使用小径材和低质材为主要原料,在一系列加工处理后,所有备料动作只需要直接刨切木料。同时,经营生产中的木器厂都存在大量废弃木料,在使用EXCEED-WMP其中的填充技术时,可以降低成本40-80%。

2.艾克西德产品不需要进行熏蒸处理:WMP不同于传统已知蒸煮处理,免除了环保困扰,不需要3-4小时以上的等待时间,更不用二次烘干。以上,避免了木质素的析出,从而解决了蒸煮后原木料着色、回弹、强度降低等一系列问题。蒸煮工艺还有一个不可跳跃的壁垒,就是对木种的挑选,必须是硬木材质,当加工成本低廉的软木料(如桦木、桉木等)时,就会在弯曲时产生褶皱,导致后续砂光时产生砂漏的显现,无法打磨修复。

3.艾克西德产品不需要高频:一、WMP不用高频机需要的铝模定型,而是充分利用木器厂现有资源,就地取材,木料完成模具制造,故尔不用定制价格昂贵的铝制模具,节省了高额的模具费用;二、避免了职员因辐射造成的职业病。世卫组织制定大于5MW/CM²的辐射量就会对人体造成伤害(流产、眼底烧伤导等),而工作中的高频机实地测量最少要达到2400MW/CM²以上的能量辐射,此时的手持辐射测量仪已经达到爆表,并自行关机。

4.避免车间改动:不用传统压机一样的地沟地基,落地即用。

5.喷漆费用、打磨费用大幅降低:光滑面在外,没有呛茬,便于打磨,减少油漆渗入。

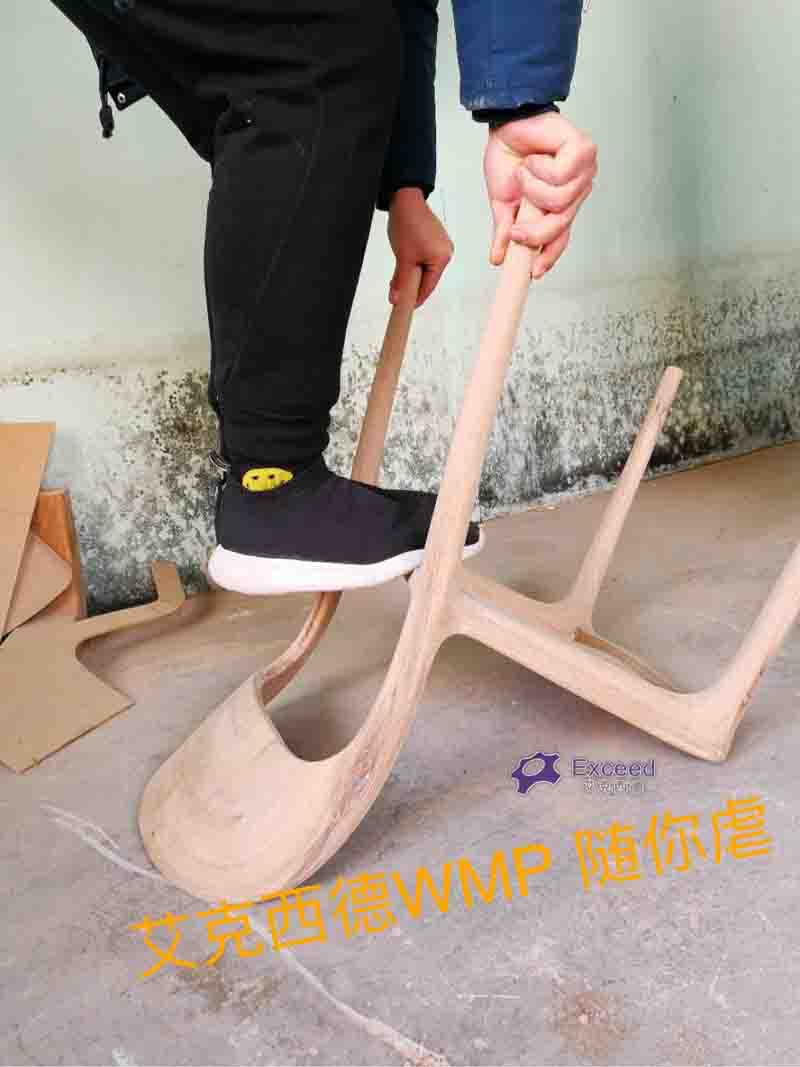

这仅仅是艾克西德产品优势的一小部分,我们的产品还有更多方面的优势,这都源于我们在弯曲木方面先进的技术。相比于传统技术生产的弯曲木,我们公司所生产的弯曲木力学性能有着很大的优势,在抗弯强度、强度变异性以及握钉力等方面,是原有工艺的3-5倍。艾克西德WMP制作的直拼板效果的木基材,即使有人悬空踩在木材上面,强大的韧性也会保护木材不会出现端口开裂、强度不足的现象。

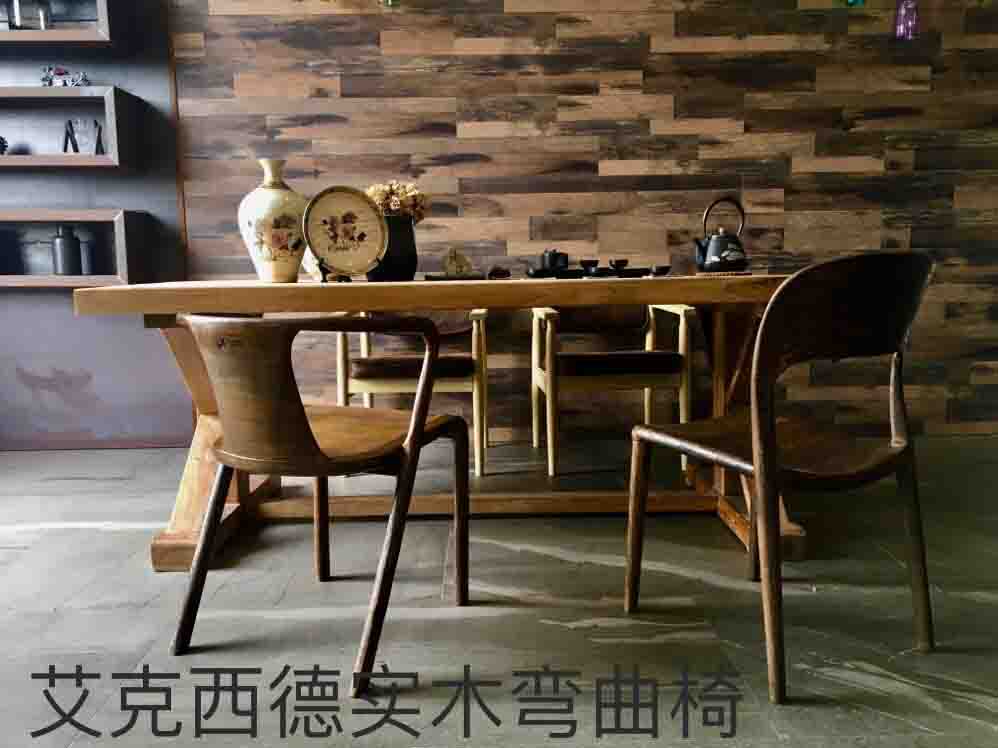

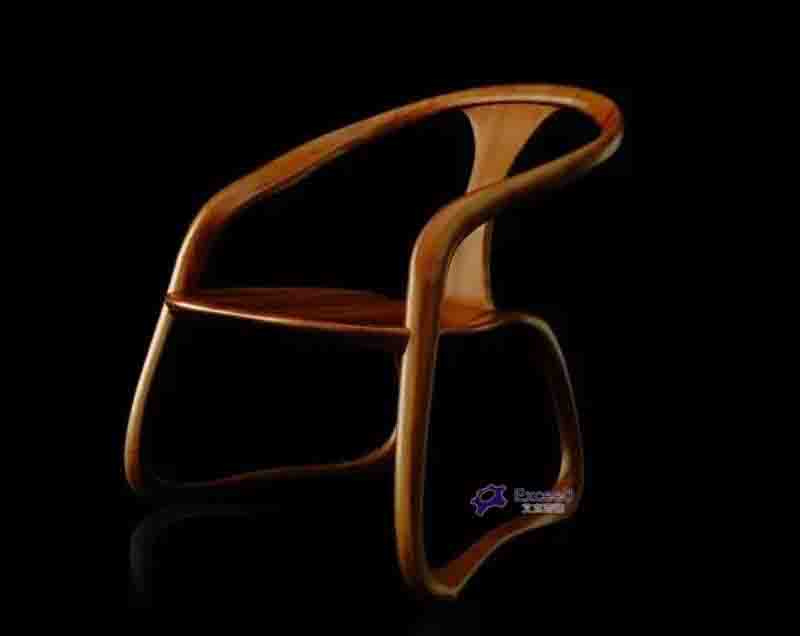

随着人们生活水平的提高,往往需要更高的生活质量。在装修方面,由于技术的落后,传统的木材不可避免的会出现绞线、指接线,这会严重性小家具的美观性。然而,WMP目前可完成2850MM整料单支成型,完美的解决的木材连接后会出现瑕疵的问题,完全实现流畅线性。依靠着这个优点,艾克西德有信心在家装领域勇担重担,争做领头羊,开创木材家具柔美外观的先河。

凭借技术上的优势,艾克西德公司所生产弯曲木备受称赞。我们公司曾邀请我们实地邀请日本国宝级匠人、意大利著名设计大师亲自审视检验应用WMP所制产品、部件等,无不表示惊叹,无不表示折服!大师们纷纷称赞艾克西德公司的技术,认为我们的技术已经领先于世界领域,在未来的发展中必将引领弯曲木的生产技术潮流。

艾克西德,将品质视为企业的生命,积极开展科研专攻项目,并严格遵循产品质量内控标注,产品全部达到并超过国家标准。为了更好地进行产品开发,公司与东北林业大学共同研制开发的烫蜡技术,与现代自动化机械相结合。这不仅传承了经典古老的工艺,更是将其与现代技术完美结合,实现了生产力的大幅度提升。在未来,艾克西德还计划与东北林业大学共同研发原木顺纹压缩弯曲技术,实现原木的二维弯曲,更突破性的实现原木的多维弯曲,超越丹麦技术,世界领先!

艾克西德拥有先进的生产和检验设备,公司以国际标准为基础,建设一流的管理团队,培养汇聚业内领军人物,以“研发创新、行销冲锋”为理念,投入大量人力、物力和财力,研发了EXCEED-WMP优化型弯曲木制品,艾克西德带动了木材领域的市场风向。公司运用优秀的销售团队、服务团队和金融团队,以诚心做好木材,让采购方免去的一切后顾之忧,真正做到安心采购。

艾克西德潜心于研究,专注于技术,方能达到如今的成就。我们对于这项技术具有权威性,不容得任何方式的窃取和侵犯!

在当前对外经济飞速发展的时代,无论在国内还是在国外越来越多的涉及到有关知识产权的争议和纠纷,随着对外改革开放的进一步深入,对我国的知识产权进行保护就显的格外重要。艾克西德 WMP项目包含艾克西德团队独立研发并拥有知识产权发明专利之技术及设备,这是公司权威性的体现,绝不允许相关人士的考察和参观,这是对艾克西德劳动成果的尊重!

我们公司推出的产品符合现代化的产品需求,无论顾客需要什么形状的产品,都可以通过设计师的设计,EXCEED-WMP的加工制造得到满足。改变了以前许多设计只能停留在电脑中的状态,把原有停留在电脑里的设计变为工业化生产的实际产品,免除理念与实际的障碍、免除现场加工的效率、成本困扰,把不可能变为可行,十分具有社会价值。而通过先进的技术,实现材料损耗大幅减少、加工时间大幅缩短。原有及现有技术采用木材加工时,由于诸多缺陷,材料损耗很大,不能用的下脚料也很多。而WMP改变了这一缺点,通过先进的技术使材料成本、人工成本、加工成本成倍递减,实现平均节约用料30%、节省用时40%,综合成本降低40%-60%,大大满足了消费者的经济需求,实现了我们企业的经济价值。

我们公司主张创新,通过不断地核心技术、推出新的木材产品来带动经济发展,产生了极高的社会价值和经济价值:

技术创新,艾克西德将传统的弯曲木加工中融入了高科技的成分,研制出了EXCEED-WMP技术,填不了木材领域在这一方面的不足。我们努力为消费者做出更加美观耐用的产品,让消费者获得更加舒适的体验。

产品创新,艾克西德改变了传统家具制作时依靠榫卯结构来达到稳固的目的,依托EXCEED-WMP创新工艺,可免除榫卯结构的复杂加工工艺,减少对技术人员的依赖,减少机加工压力。原始毛坯木料经WMP技术处理后,保持木纹理顺纹平行排列,保持原有断面文理,自然呈现,并强化了木料的坚韧性,给消费者带来原木的淳朴之风。

艾克西德通过自身的努力创造出了这项先进的技术,然而我们并不想独善其身,我们希望通过我们的技术,为整个社会带来福利。

我们会现在新的技术起点,坦然面对未来的机遇和挑战,在瞬息万变的市场中不断超越自我,积极创新。与广大合作伙伴携手共赢,共创新的辉煌,向着打造行业标杆的目标奋力前行!

感谢日本川崎秀之先生、丹麦汉斯先生等多位大师对我公司实木弯曲技术的肯定与支持!

In the process of bending wood development, the WMP of EXCEED, like a heavy bomb, has attracted wide attention in the industry. EXCEED WMP came out, overturning all previous knowledge of bending wood material preparation method, bending dimension and processing technology! Relying on the advanced technology of bending wood processing, EXCEED has great advantages in all aspects:

1. The products of EXCEED can greatly reduce the cost: WMP uses small-diameter wood and low-quality wood as the main raw materials. After a series of processing, all the material preparation actions only need to directly plane and cut wood. At the same time, there are a lot of waste wood in the wood industry. When using the filling technology of excel-wmp, the cost can be reduced by 40-80%.

2. EXCEED products do not need to be fumigated: WMP is different from the traditional known cooking treatment, which avoids environmental problems, does not need more than 3-4 hours of waiting time, let alone secondary drying. Above all, the precipitation of lignin is avoided, and a series of problems such as coloring, rebound and strength reduction of raw wood after cooking are solved. There is also a non jumping barrier in cooking process, that is, the selection of wood species must be made of hardwood. When processing low-cost soft wood materials (such as birch, eucalyptus, etc.), wrinkles will occur when bending, resulting in the appearance of sand leakage in subsequent sanding, which cannot be polished and repaired.

3. EXCEED's products do not need high frequency: first, WMP does not need the aluminum mold required by the high frequency machine, but makes full use of the existing resources of the woodwork factory, takes local materials and completes the mold manufacturing with wood, so we do not need to customize expensive aluminum mold, which saves the high mold cost; second, we avoid the occupational disease caused by the radiation of the staff. The radiation of more than 5MW / cm? Developed by who will cause harm to human body (abortion, eyeground burn guide, etc.), while the field measurement of the high-frequency machine in work should reach at least 2400mw / cm? Of energy radiation, at this time, the hand-held radiation meter has reached the explosion level and shut down by itself.

4. Avoid workshop modification: do not use the trench foundation like the traditional press, and use it on the ground.

5. The cost of painting and polishing is greatly reduced: the smooth surface is outside without choking, which is convenient for polishing and reduces the penetration of paint.

This is only a small part of the advantages of our products. Our products have more advantages, which are all due to our advanced technology in bending wood. Compared with the bending wood produced by traditional technology, the mechanical properties of the bending wood produced by our company have great advantages. In terms of bending strength, strength variability and nail holding force, it is 3-5 times of the original technology. The wood base material with the effect of straight panel made by WMP of EXCEED, even if someone is standing on the wood in the air, the strong toughness will protect the wood from the phenomenon of port cracking and insufficient strength.

With the improvement of people's living standards, higher quality of life is often needed. In terms of decoration, due to the backward technology, the traditional wood will inevitably appear stranded wire and finger wire, which will seriously affect the beauty of small furniture. However, at present, WMP can complete 2850mm single piece molding, perfectly solve the problem of defects after wood connection, and fully realize smooth linearity. Relying on this advantage, EXCEED is confident to shoulder the heavy burden in the field of home decoration, strive to be the leader, and create a forerunner of soft and beautiful appearance of wood furniture.

Thanks to its technical advantages, the curved wood produced by EXCEED is highly praised. Our company has invited us to invite Japanese national treasure level craftsmen and famous Italian design masters to examine and test the products and parts made by WMP in person, all of which express surprise and admiration! The masters praised the technology of EXCEED one after another, and believed that our technology has been ahead of the world field, and will definitely lead the production technology trend of bent wood in the future development.

EXCEED regards quality as the life of the enterprise, actively carries out scientific research projects and strictly follows the internal control mark of product quality. All products meet and exceed the national standards. In order to better develop the products, the company and Northeast Forestry University jointly developed the hot wax technology, which is combined with modern automation machinery. This not only inherits the classic and old technology, but also perfectly combines it with modern technology, achieving a substantial increase in productivity. In the future, EXCEED also plans to work with the Northeast Forestry University to develop the technology of compression bending along the grain of logs, to realize the two-dimensional bending of logs, to achieve the multi-dimensional bending of logs more groundbreaking, to surpass the Danish technology, and to be the world leader!

EXCEED has advanced production and inspection equipment. Based on international standards, the company has built a first-class management team, trained and gathered industry leaders, and developed the optimized bending wood products of EXCEED-wmp with the concept of "R & D innovation and marketing rush". EXCEED has driven the market trend in the wood field. The company uses excellent sales team, service team and financial team to do a good job in wood with sincerity, so that the purchaser can avoid all worries and truly achieve secure procurement.

Only by focusing on research and technology can EXCEED achieve what he has achieved. We are authoritative for this technology, and can not be stolen or violated in any way!

In the current era of rapid development of foreign economy, whether at home or abroad, more and more disputes and disputes related to intellectual property rights are involved. With the further deepening of reform and opening up, it is particularly important to protect intellectual property rights in China. The EXCEED WMP project includes the technology and equipment independently developed by the EXCEED team and owned the intellectual property invention patent. This is the authoritative embodiment of the company, and it is not allowed to be inspected and visited by relevant people. This is the respect for the labor achievements of ecsid!

Our company's products meet the needs of modern products. No matter what shape of products customers need, they can be met through the design of designers and the processing and manufacturing of EXCEED-wmp. It has changed the state that many designs can only stay in the computer before, changed the original design that stays in the computer into the actual product of industrial production, exempted the obstacles of concept and reality, exempted the efficiency and cost of on-site processing, and changed the impossibility into feasibility, which is of great social value. Through advanced technology, material loss and processing time can be greatly reduced. When the original and existing technologies adopt wood processing, due to many defects, the material consumption is very large, and there are many leftovers that cannot be used. WMP has changed this disadvantage. Through advanced technology, material cost, labor cost and processing cost are reduced by multiple times. It can save 30% of material and 40% of time on average, and reduce 40% - 60% of comprehensive cost. It can greatly meet the economic needs of consumers and realize the economic value of our enterprise.

Our company advocates innovation. Through continuous core technology and introduction of new wood products to drive economic development, it has generated high social and economic value:

With technological innovation, EXCEED-wmp technology has been developed by integrating the traditional bending wood processing with high-tech elements, which can not fill the shortage of wood field in this aspect. We strive to make more beautiful and durable products for consumers, so that consumers can get a more comfortable experience.

Product innovation, EXCEED changed the traditional furniture production to rely on mortise and tenon structure to achieve a stable purpose. Relying on the EXCEED-wmp innovation process, it can avoid the complex processing technology of mortise and tenon structure, reduce the dependence on technical personnel and reduce the machining pressure. After being treated by WMP technology, the original rough wood will keep the parallel arrangement of the grain, keep the original section and natural appearance, strengthen the tenacity of the wood, and bring the simplicity of the log to the consumers.

EXCEED created this advanced technology through his own efforts, but we do not want to be alone. We hope to bring benefits to the whole society through our technology.

We will take a new technology starting point now, face the opportunities and challenges in the future, and continue to surpass ourselves and innovate actively in the rapidly changing market. We will work with our partners to achieve win-win results, create brilliant achievements and forge ahead with the goal of building industry benchmark!

Thank for Mr. Hideki Kawasaki of Japan, Mr. Hans of Denmark and many other masters for your affirmation and support for our solid wood bending technology!